Digital Fabrication

With the rapid proliferation of low-cost CNC manufacturing machines, building designers are increasingly able to harness digital fabrication techniques to streamline the design-to-fabrication process. This streamlining arises from the direct integration of computer-aided design (CAD), computer-aided manufacture (CAM), and CNC machinery processes, with key benefits of such integration being increased design flexibility and direct control of manufactured elements. Construction benefits can also be realised in terms of reduced time and cost, with a digitally-fabricated building element capable of possessing part identifiers, assembly information, or integral joints.

Digital fabrication research at the UQ Folded Structures Lab is focused on developing computational design-to-fabrication methods for lightweight, portable, and low-cost structural systems.

Folded Sandwich Structures

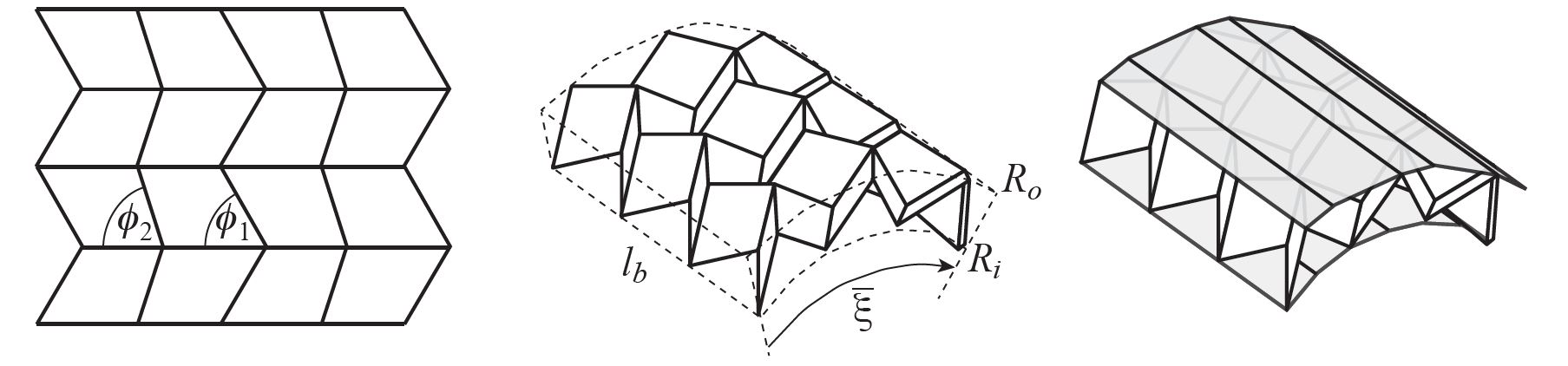

A novel structural form, termed folded sandwich structures, is developed for ultra-light architectural-scale constructions. These structures are crafted by attaching faceted inner and/or outer face sheets to a folded plate core pattern. The faceted faces offer two key advantages: they enable robust, continuous edge connections between core and face layers, and they allow the assembly of unbent, rigid materials like metals and composites into complex curved geometries. Further information: DOI:10.1016/j.autcon.2015.12.002.

Folded Timber Sandwich Structures

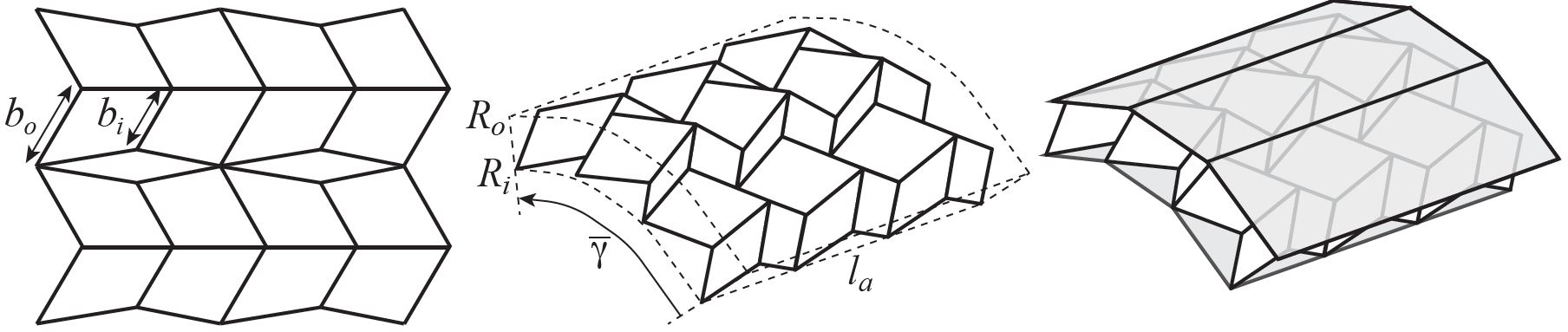

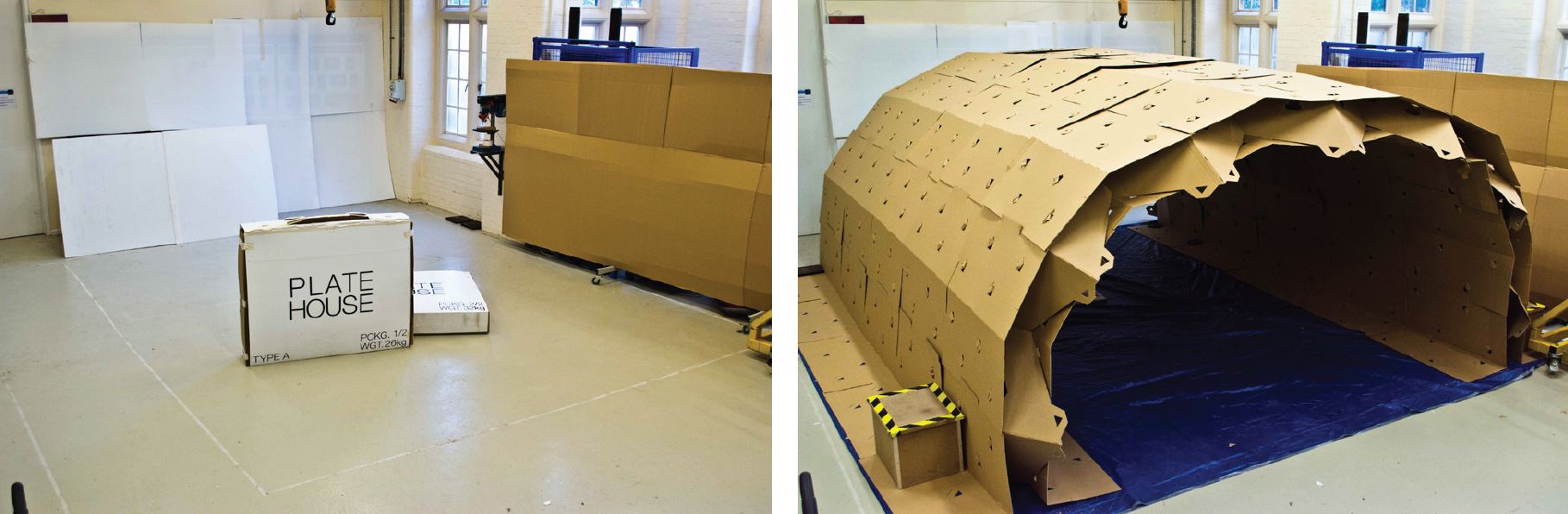

This paper outlines a design-to-fabrication process for a new timber sandwich structure, merging folded assembly and integral mechanical joints, and examines its efficacy for modular timber construction. The digital design includes methods for segmenting and unfolding building profiles and fabricating timber sandwich panels with press-fit and rotational press-fit (RPF) joints. Validation includes constructing a 30m2 house and a 42m2 canopy, both demonstrating high assembly accuracy and speed. 3D scanning and defect analysis confirm the precision of the structures, with most surface errors and angular defects in rotational press-fit joints being minimal. Further information: DOI:10.1016/j.autcon.2019.01.008.

Subsequent research then investigates the mechanical behavior of folded timber sandwich structures featuring the RPF joints. Six arches are tested under varied load cases to induce sagging and hogging at internal joints. The experiments reveal failures at joints under maximum hogging moment, with two types observed: FRP tensile fracture and core compressive rupture. A nonlinear static analysis and a simplified 2D frame model are proposed to predict these failures. The model treats the RPF joint as a nonlinear semi-rigid hinge with a bilinear moment-curvature relationship, derived from joint strain data during testing. Core compressive failures are attributed to inelastic core buckling due to misalignment in core segments. Further information: DOI:10.1016/j.tws.2021.108345.

Post-Tensioned Deployable Timber Structure

This paper explores the computational design and digital fabrication of a novel deployable timber structure, termed a ‘mass timber stressed arch’. This system transforms from flat to a curved structure through rotational assembly and post-tensioning. It introduces two design techniques: a subdivision scheme for efficient manufacturing of arch modules, and a hybrid joint system for managing kinematic freedoms and fixities between modules. The process is validated by constructing and installing a full-scale timber arch pavilion, with experimental testing revealing high load capacity and identifying shearing of the pin connection between modules as the ultimate failure mode. Further information: DOI:10.20898/j.iass.2019.199.030.

Funicular Timber Structures

This research develops a digital form-finding model that integrates funicular geometry with a material inventory constraint, focusing on material efficiency and waste reduction. It ensures structural equilibrium using funicular geometry and optimizes the use of utility-grade sawn timber, which often has structural variability and defects leading to rejection for structural applications. By removing defects, usable short length members are created from up to 50% of sawn timber rejected by Australian sawmills. These short members are ideal for articulated structures that employ inverted funicular geometry, incurring only axial stresses and allowing simple timber connections. The study demonstrates the structural viability of this approach with a prototype pavilion, showcasing a potential solution to reduce waste in the timber industry. Further information: DOI:10.1007/s42452-020-03314-9.

Related Publications

Bahremandi-Tolou, M., Wang, C., Gattas, J. M., & Luo, D. (2024). Curved surface form-finding with self-shaping perforated plates. Architectural Intelligence, 3(1), 1-16. https://doi.org/10.1007/s44223-024-00059-y

Baber, K. R., Barton, A., Burry, J. R., Chen, C., Gattas, J. M., Koch, C., & Ren, H. (2023). Inventory-constrained design of a variable small diameter round timber structure. In Proceedings of IASS annual symposia (Vol. 2023, pp. 1–12). International Association for Shell; Spatial Structures (IASS).

Alqaryouti, Y., Fernando, D., & Gattas, J. M. (2021). Structural behaviour of folded timber sandwich structures. Thin-Walled Structures, 169, 108345. https://doi.org/10.1016/j.tws.2021.108345

Baber, K. R., Burry, J. R., Chen, C., Gattas, J. M., & Bukauskas, A. (2020). Inventory constrained design of a timber funicular structure. SN Applied Sciences, 2(9), 1–19. https://doi.org/10.1007/s42452-020-03314-9

Baber, K. R., BURRY, J. R., CHEN, C., GATTAS, J. M., & BUKAUSKAS, A. (2019). Inventory constrained funicular modelling. In Proceedings of the IASS annual symposium 2019 ’form and force’.

Plasencia Alava, K. B., McCann, L. K., Hodge, G., Baber, K., & Gattas, J. M. (2019). Computational design and experimental behaviour of deployable mass timber arches. Journal of the International Association for Shell and Spatial Structures, 60(1), 90–100. https://doi.org/10.20898/j.iass.2019.199.030

Plasencia Alava, K. B., McCann, L., Baber, K., & Gattas, J. M. (2018). Reconfigurable assemblies of a deployable mass timber structure. In Proceedings of the IASS annual symposium 2018 ’creativity in structural design’.

Al-Qaryouti, Y., Baber, K., & Gattas, J. M. (2019). Computational design and digital fabrication of folded timber sandwich structures. Automation in Construction, 102, 27–44. https://doi.org/10.1016/j.autcon.2019.01.008

Al-Qaryouti, Y., Wen, Y., Fernando, D., & Gattas, J. M. (2017). Comparison of plate and shell timber-composite sandwich structures. In Proceedings of IASS annual symposia (Vol. 2017, pp. 1–8). International Association for Shell; Spatial Structures (IASS). Retrieved from https://www.ingentaconnect.com/contentone/iass/piass/2017/00002017/00000017/art00001?crawler=true&mimetype=application/pdf

Gattas, J. M., & You, Z. (2016). Design and digital fabrication of folded sandwich structures. Automation in Construction, 63, 79–87. https://doi.org/10.1016/j.autcon.2015.12.002