FRP-Timber Composites

Hybrid FRP-timber (HFT) structures merge FRP (fibre reinforced polymer) with timber veneers, forming high-performance, lightweight structural members optimized for composite properties and maximum load-bearing capacity. These members exploit the orthotropic properties of both materials by aligning fibre directions and employing efficient thin-walled cross-sectional shapes for optimal performance. Further information: DOI:10.1177/1369433217739709.

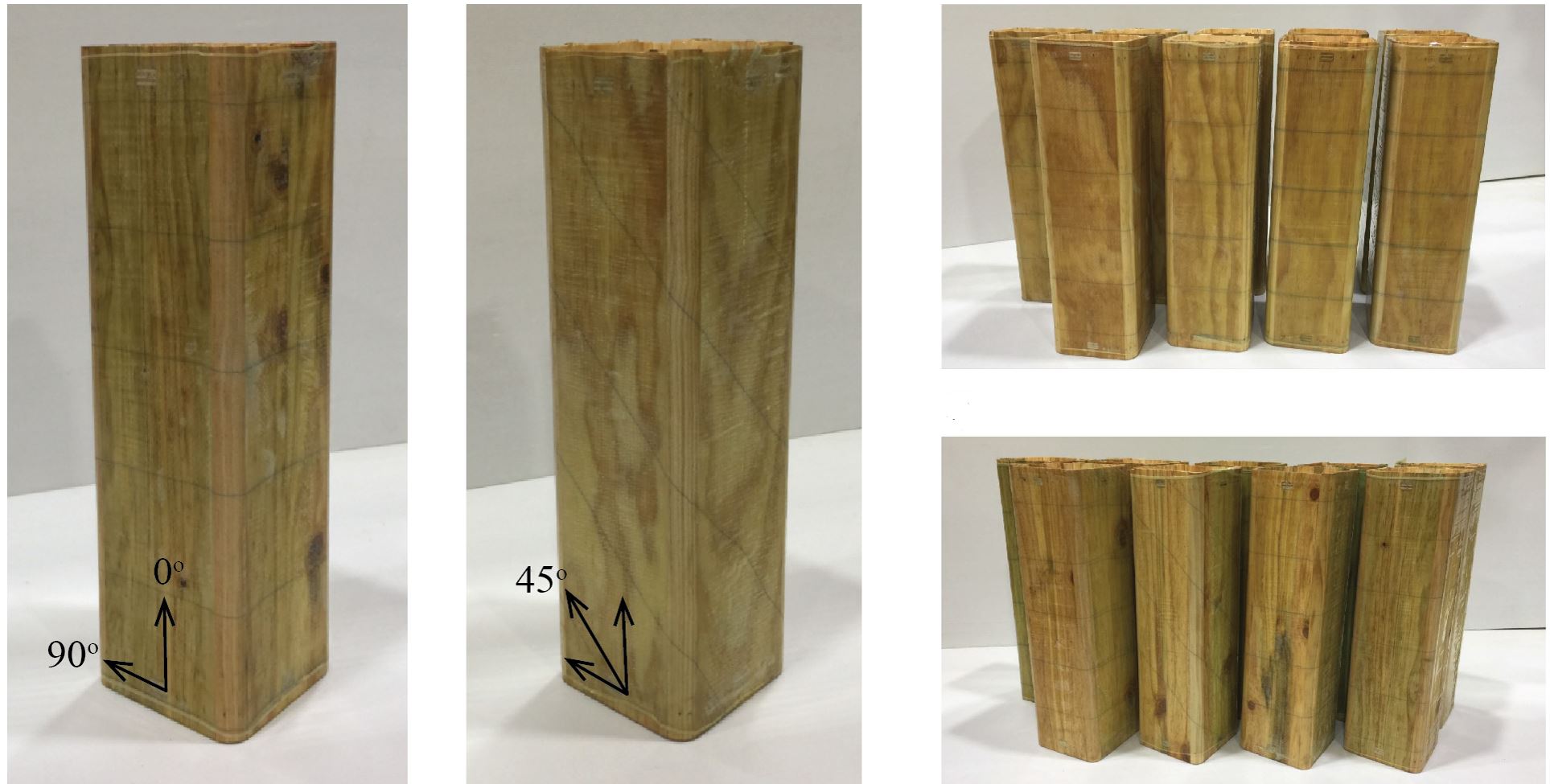

Folded Hybrid FRP-Timber Sections

This research develops two innovative folding fabrication processes for HFT thin-walled sections, enhancing geometric and material design possibilities. Initially applied to regular hollow sections, a geometric design method is also presented for any folded structure with a non-intersecting polygonal chain cross-section. An experimental study shows that FHFT columns have double the compressive capacity of plywood-only columns and a weight-specific compressive strength comparable to commercial steel hollow sections. Further information: DOI:10.1016/j.tws.2017.10.007.

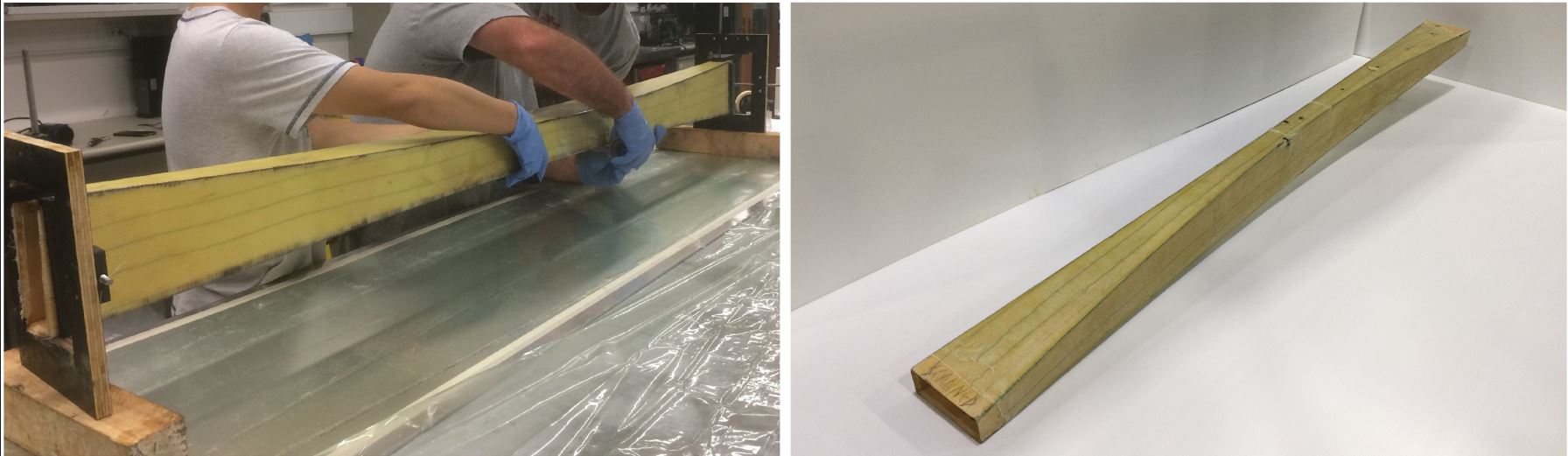

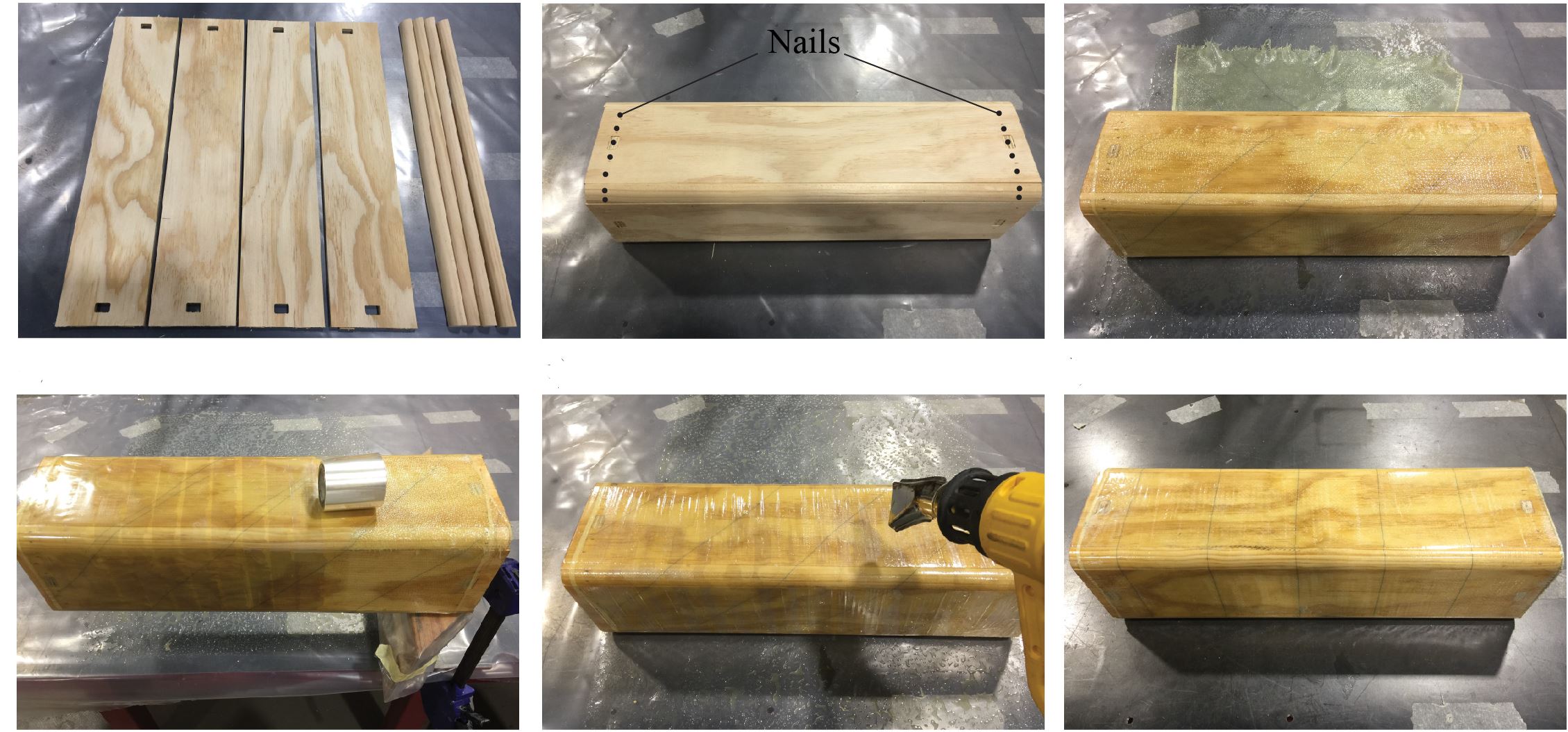

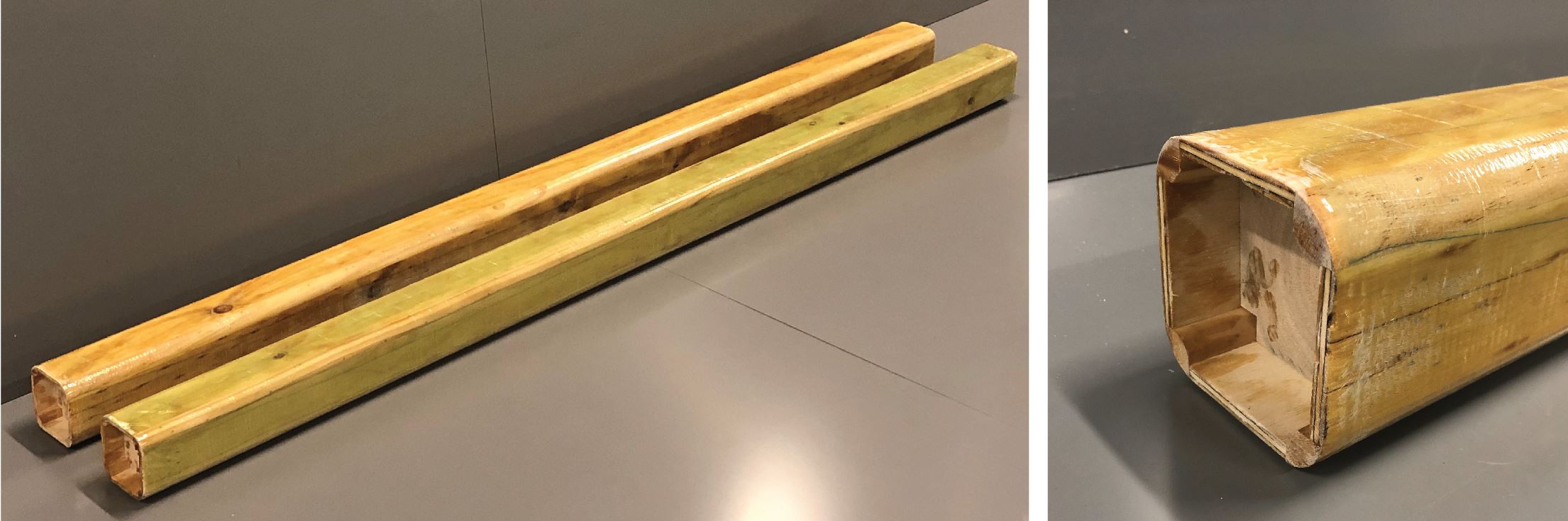

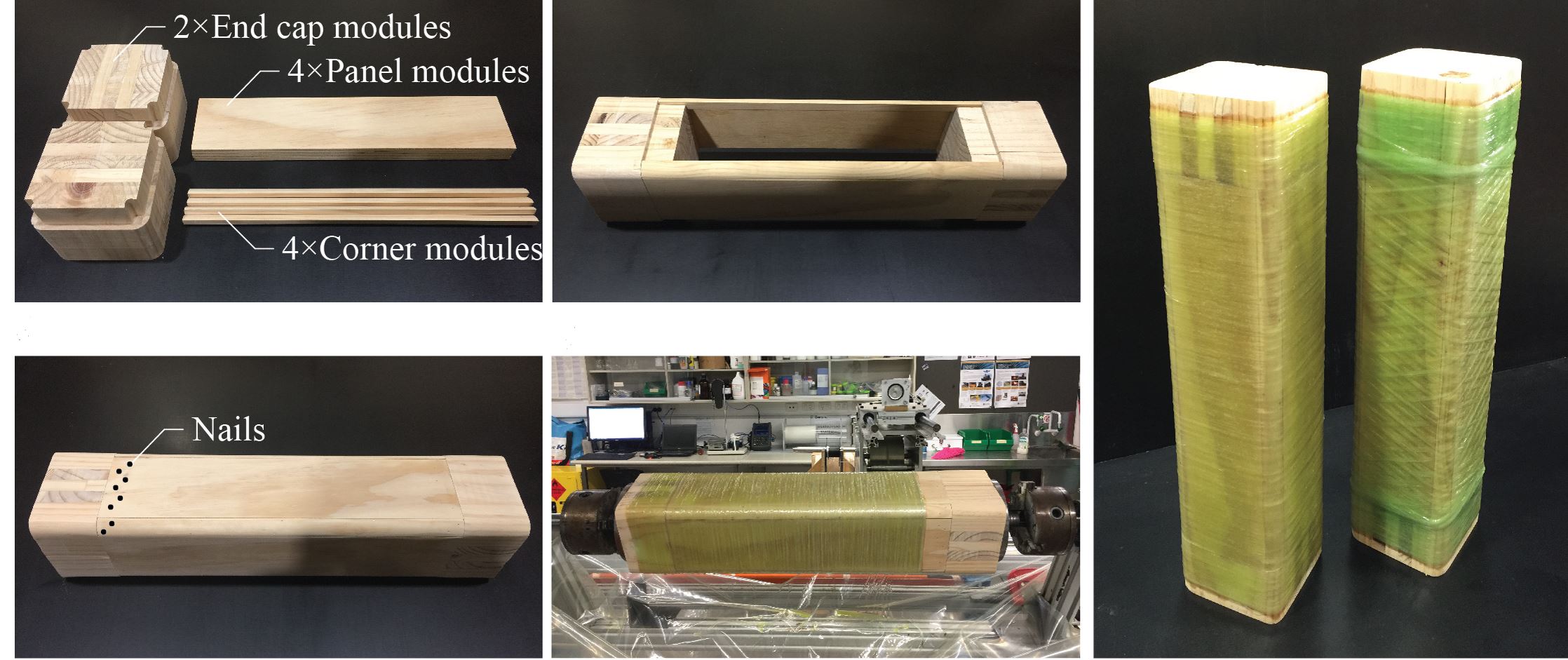

Modular HFT Sections

Based on the observations of folded HFT sections, an improved ‘modular’ manufacturing method was developed for HFT sections. The process was demonstrated for manufacturing structural square hollow sections, including experimental and numerical studies on stub columns under uniaxial compression examining the impact of FRP and timber material choices on structural performance. Results indicate that GFRP wrapping significantly influences behavior, transitioning from buckling to crushing failure and increasing strength and stiffness with added GFRP layers. Compared to previous folded HFT sections, modular HFT sections exhibit a 69% increase in strength and a 38% improvement in strength-to-weight ratio. Further information: DOI:10.1016/j.compstruct.2020.113506.

Hybrid Timber-Concrete Floor Panel Systems

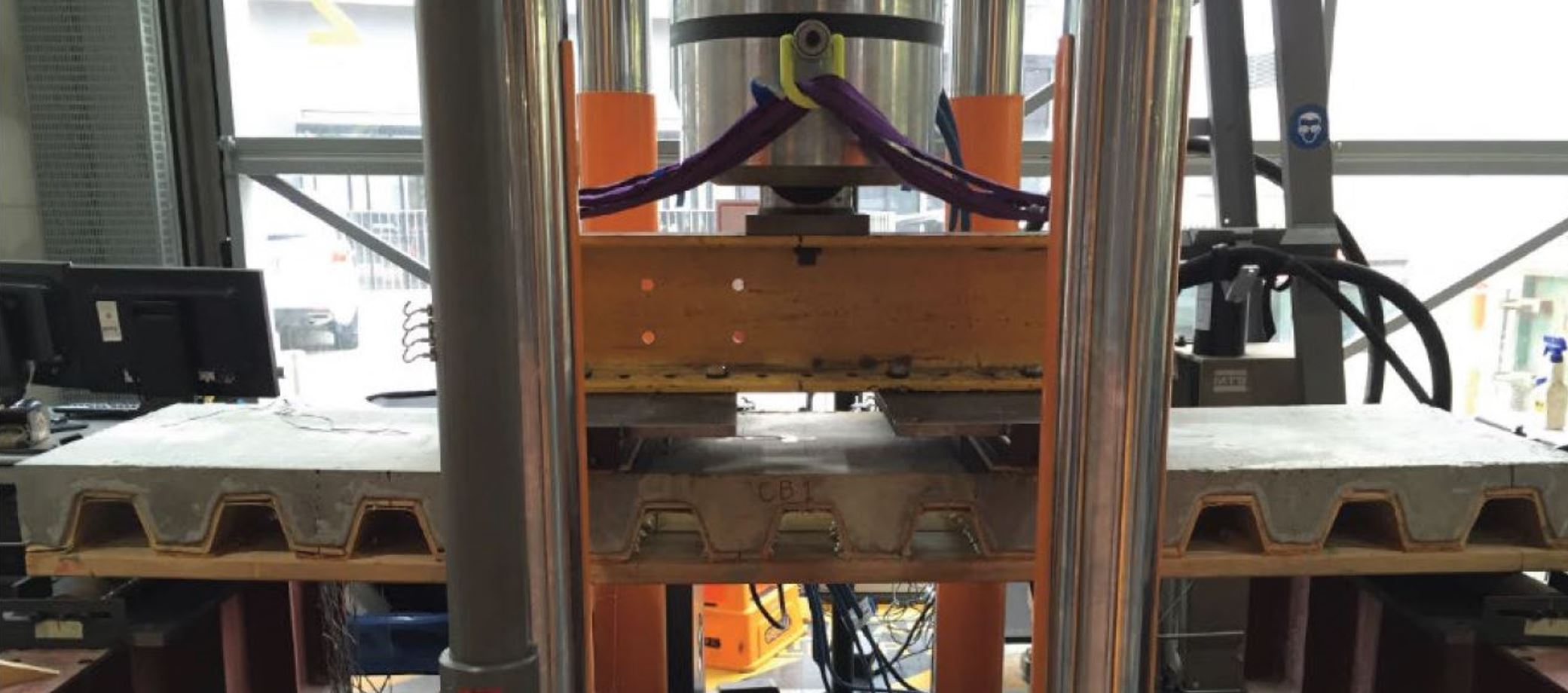

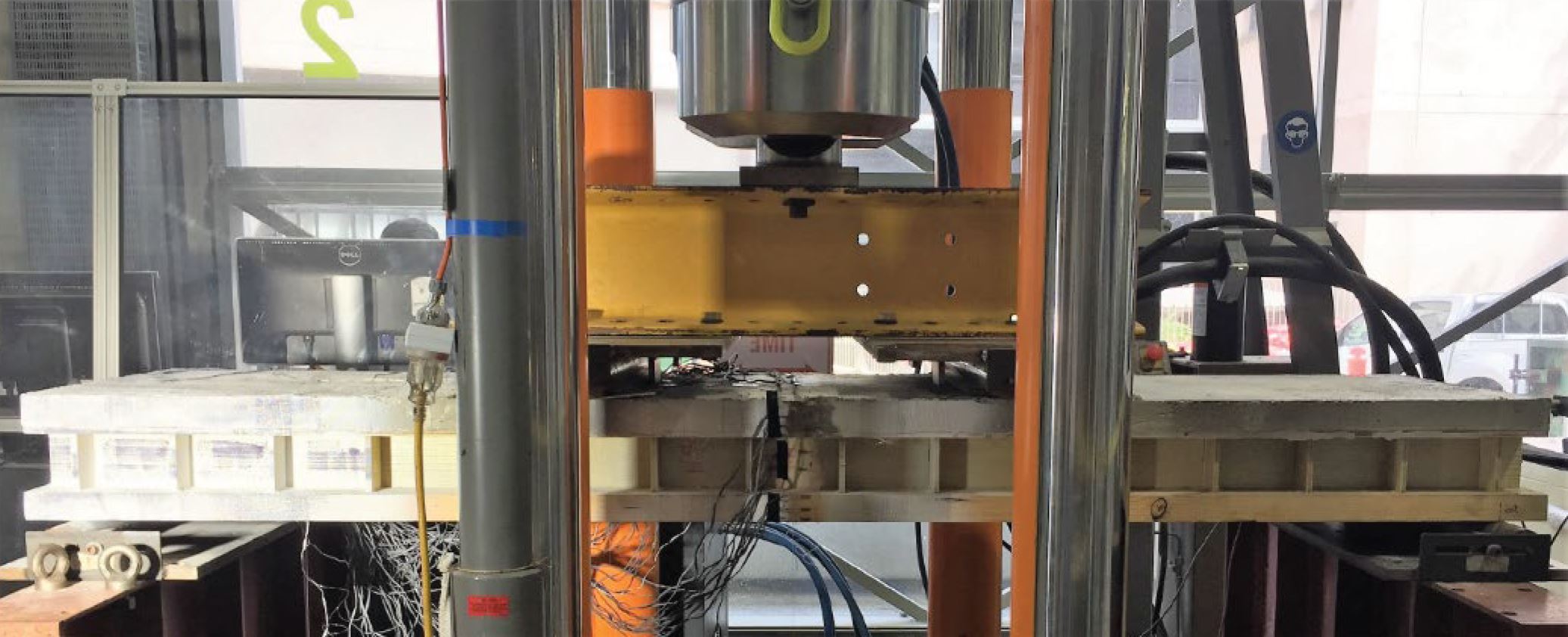

Novel ‘Hybrid Timber-Concrete Corrugated’ floor panel systems were developed as an advancement over conventional Hybrid Timber-Concrete (HTC) systems. The first developed system features a corrugated core placed between timber and concrete layers. It hypothesizes an increased weight-specific flexural capacity by reducing concrete volume without compromising strength. Experimental testing on HTCC panel flexural capacities, failure modes, core geometries, shear force transfer, and composite action, found cores with longitudinal orientation had a 73% ultimate moment carrying efficiency and 85% stiffness efficiency at service load compared to an idealized full-composite HTC section. Further information: DOI:10.1016/j.engstruct.2019.109832.

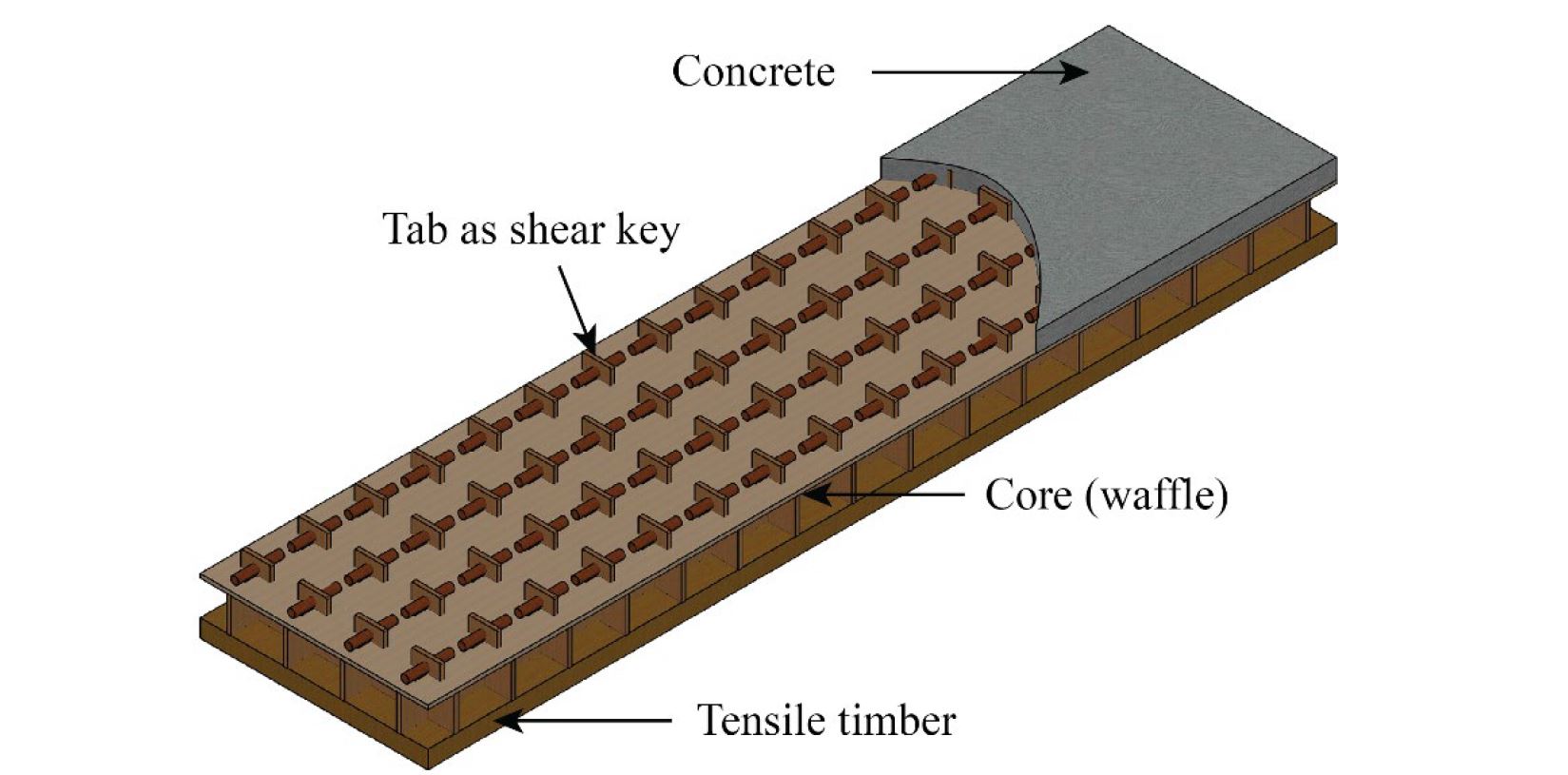

A second novel HTC system was the developed with a fibre reinforced polymer-timber waffle-shaped core. Digital fabrication techniques and computer-numerical control machines were used in the core component fabrication, resulting in ease of fabrication, high accuracy, and streamlined manufacture process. Results from panel testing show that the proposed system has an extremely high flexural capacity, and demonstrated a high ductility before ultimate failure. Comparison shows the proposed system outperformed the equivalent reinforced concrete and hybrid timber-concrete panels regarding weight specific moment capacity. Further information: DOI:10.1016/j.conbuildmat.2019.08.048.

FRP-Reinforced Laminated Timber Products

This research investigates small-scale testing as an alternative to full-scale tests for timber and timber-hybrid systems, focusing on serviceability measures like natural frequency and stiffness in long-span systems. It examines the ‘size effect’ in Glulam and carbon fibre reinforced Glulam beams, comparing full-scale and half-scale beams’ dynamic and static performances. Results indicate minor scale impact on serviceability, but a significant size effect on strength, with full-scale samples showing lower strength. Tension-only reinforcement in hybrid beams seems to reduce this size effect. Further information: DOI:10.1016/j.conbuildmat.2023.130563.

Related Publications

Bravo, T. P., Gattas, J. M., Bravo, F., Astroza, R., & Maluk, C. (2024). Experimental assessment of modal properties of hybrid CFRP-timber panels. Construction and Building Materials, 438, 137075. https://doi.org/10.1016/j.conbuildmat.2024.137075

Cui, W., Gattas, J. M., & Heitzmann, M. T. (2024). Manufacture and structural performance of modular hybrid FRP–timber thin-walled beams. Construction and Building Materials, 435, 136705. https://doi.org/10.1016/j.conbuildmat.2024.136705

Tetlak, T. B., Gattas, J. M., & Maluk, C. (2023). Experimental study on the effects of scale on the static and dynamic behaviour of glulam and hybrid-glulam beams. Construction and Building Materials, 369, 130563. https://doi.org/10.1016/j.conbuildmat.2023.130563

Bravo Tetlak, T., Gattas, J. M., & Maluk, C. (2023). Scaling study on viscous damping for glulam and hybrid glulam-FRP beams. In. World Conference on Timber Engineering (WCTE 2023).

Cui, W., Fernando, D., Heitzmann, M., & Gattas, J. M. (2021). Manufacture and structural performance of modular hybrid FRP-timber thin-walled columns. Composite Structures, 260, 113506. https://doi.org/10.1016/j.compstruct.2020.113506

Ya, O., Fernando, D., Sriharan, J., Gattas, J. M., & Zhang, S. (2021). A nonlinear beam-spring-beam element for modelling the flexural behaviour of a timber-concrete sandwich panel with a cellular core. Engineering Structures, 244, 112785. https://doi.org/https://doi.org/10.1016/j.engstruct.2021.112785

Ou, Y., Gattas, J. M., Fernando, D., & Torero, J. L. (2019). Experimental investigation of a timber-concrete floor panel system with a hybrid glass fibre reinforced polymer-timber corrugated core. Engineering Structures, 109832. https://doi.org/10.1016/j.engstruct.2019.109832

Ou, Y., Fernando, D., & Gattas, J. M. (2019). Experimental investigation of a novel concrete-timber floor panel system with digitally fabricated FRP-timber hollow core component. Construction and Building Materials, 227, 116667. https://doi.org/10.1016/j.conbuildmat.2019.08.048

Fernando, D., Torero, J. L., Gattas, J., Baber, K., Maluk, C., & Hidalgo, J. P. (2018). Novel technologies for tall timber buildings: Research streams and three solutions.

Gattas, J. M., O’Dwyer, M. L., Heitzmann, M. T., Fernando, D., & Teng, J. (2018). Folded hybrid FRP-timber sections: Concept, geometric design and experimental behaviour. Thin-Walled Structures, 122, 182–192. https://doi.org/10.1016/j.tws.2017.10.007

Ou, Y., Fernando, D., & Gattas, J. M. (2017). Novel hybrid FRP-timber-concrete floor panel system. In APFIS2017-6th asia-pacific conference on FRP in structures, singapore (pp. 1–7). Retrieved from https://www.research.ed.ac.uk/en/publications/novel-hybrid-frp-timber-concrete-floor-panel-system

Fernando, D., Teng, J., Gattas, J., & Heitzmann, M. (2017). Hybrid fibre-reinforced polymer–timber thin-walled structural members. Advances in Structural Engineering, 1369433217739709. https://doi.org/10.1177/1369433217739709

Fernando, D., Gattas, J. M., Teng, J. G., & Heitzmann, M. (2015). Hybrid thin-walled members made of FRP and timber. In The 12th international symposium on fiber reinforced polymers for reinforced concrete structures (FRPRCS-12) and the 5th asia-pacific conference on fiber reinforced polymers in structures (APFIS-2015) joint conference. Retrieved from https://espace.library.uq.edu.au/view/UQ:298c828