Thin-Walled (Folded) Structures

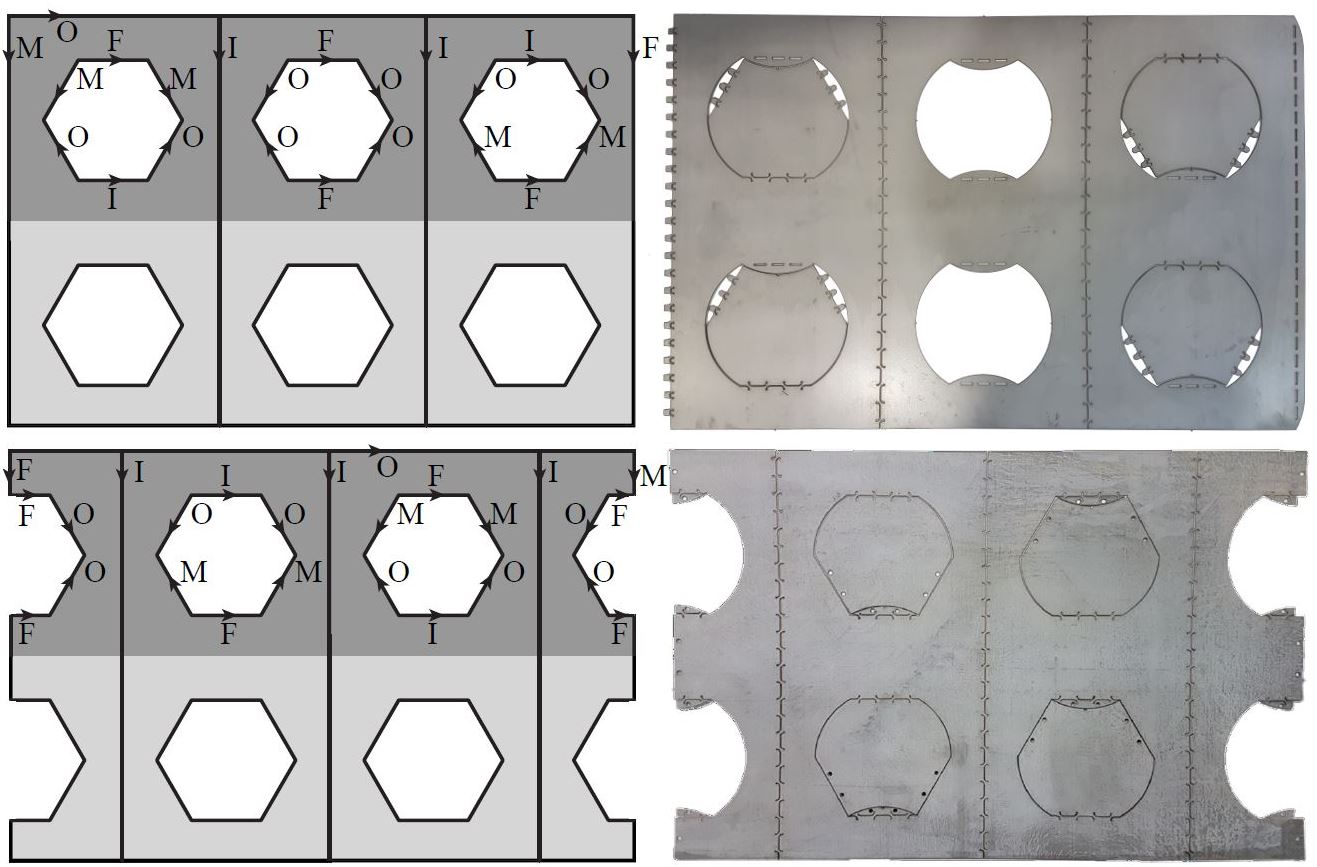

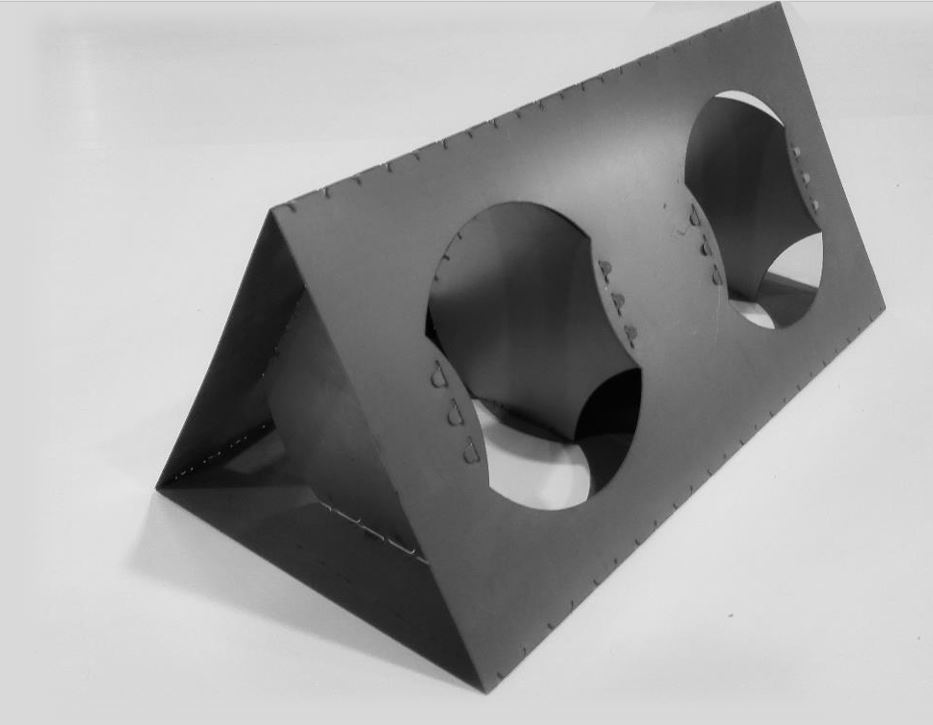

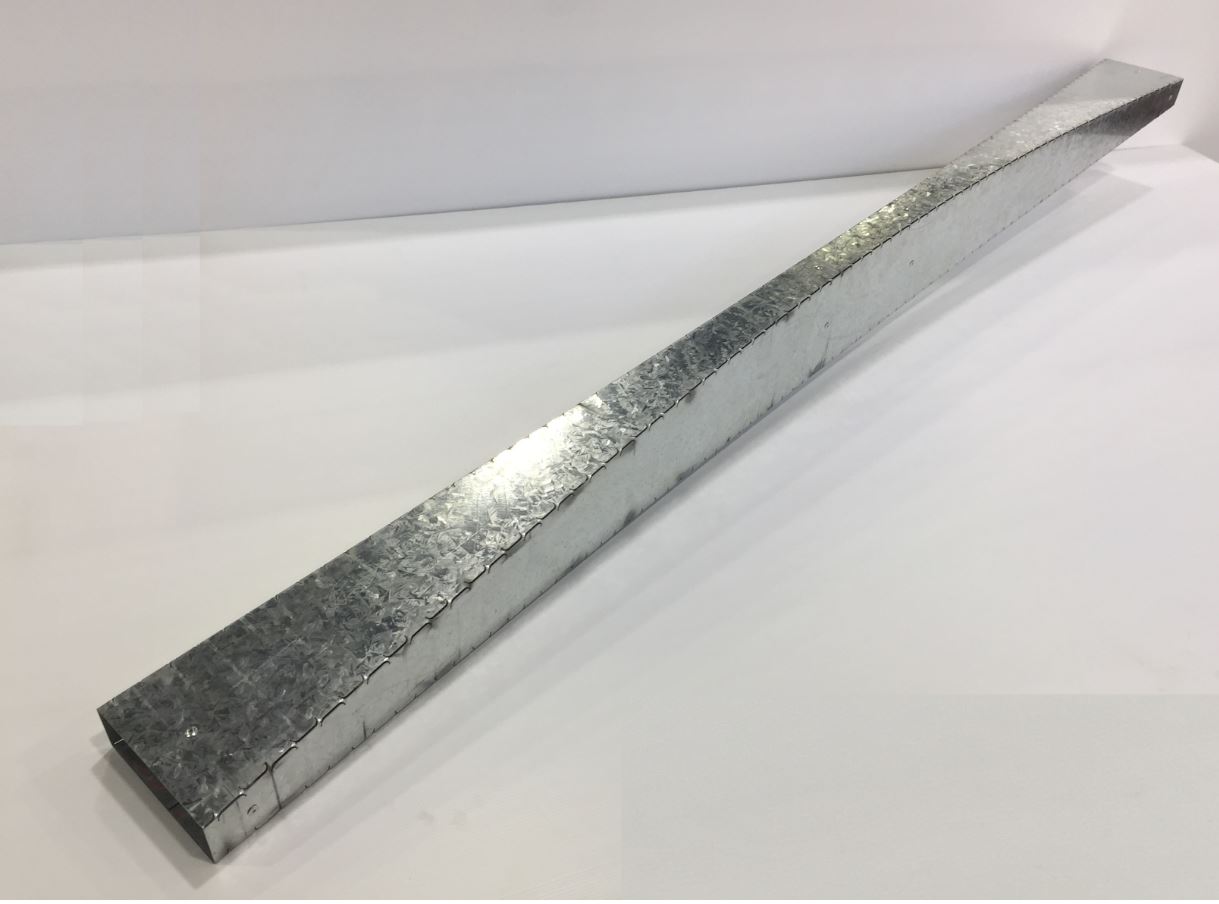

Folded Steel Structures

Novel folded assembly methods for thin-walled steel construction are developed, utilizing parametric and digitally-fabricated hinge lines. These structures are evaluated for assembly effort, manufacturing accuracy, and structural performance. Manufacturing accuracy, assessed by 3D digital image correlation and scanning, achieves precision within 50% of plate thickness even with unskilled assembly. Structural performance under uniaxial compressive load, analyzed both experimentally and numerically, confirms that conventional thin-walled steel analysis techniques effectively model folded structure behaviors. Further information: DOI:10.1016/j.jcsr.2017.07.010.

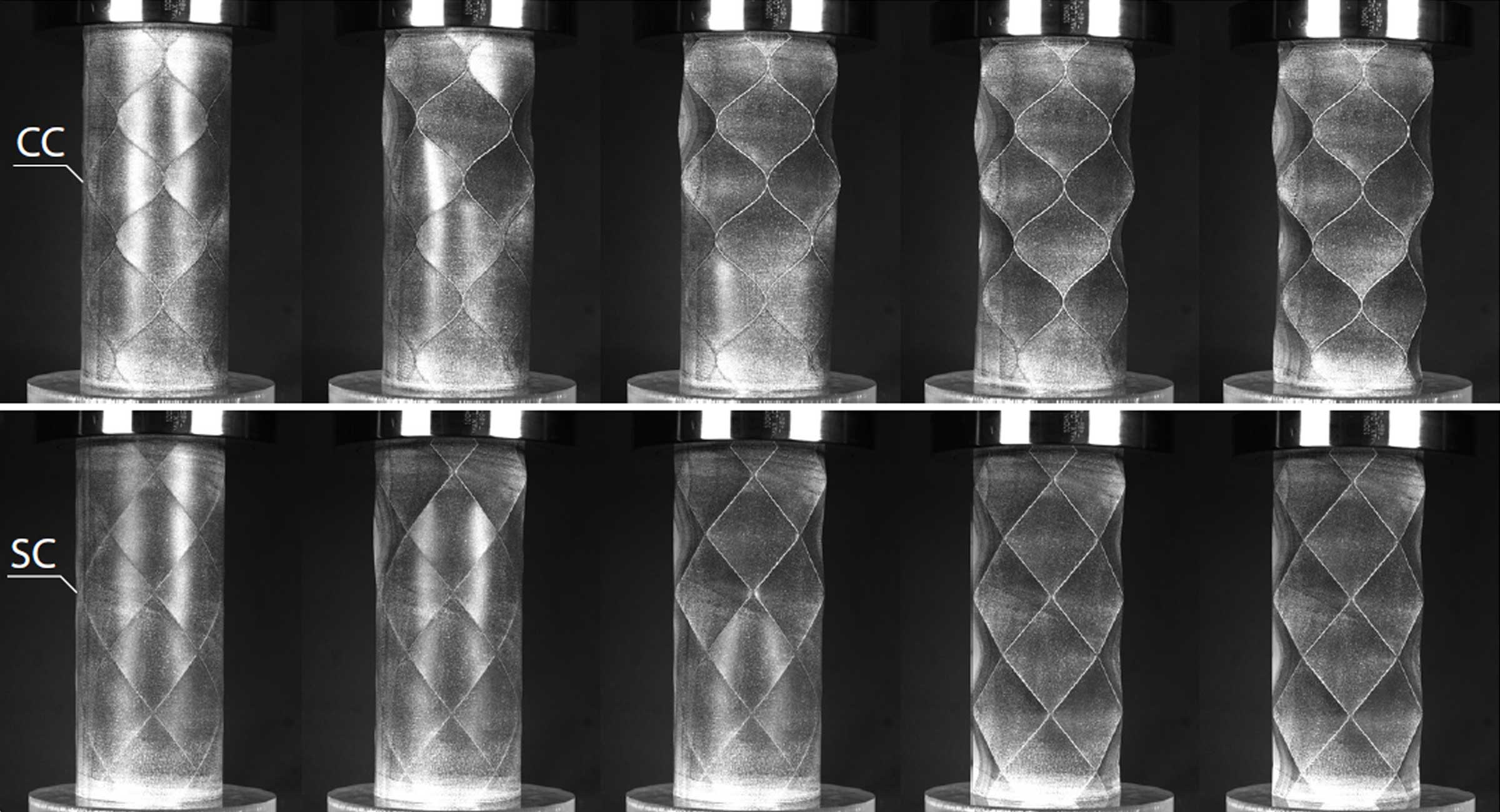

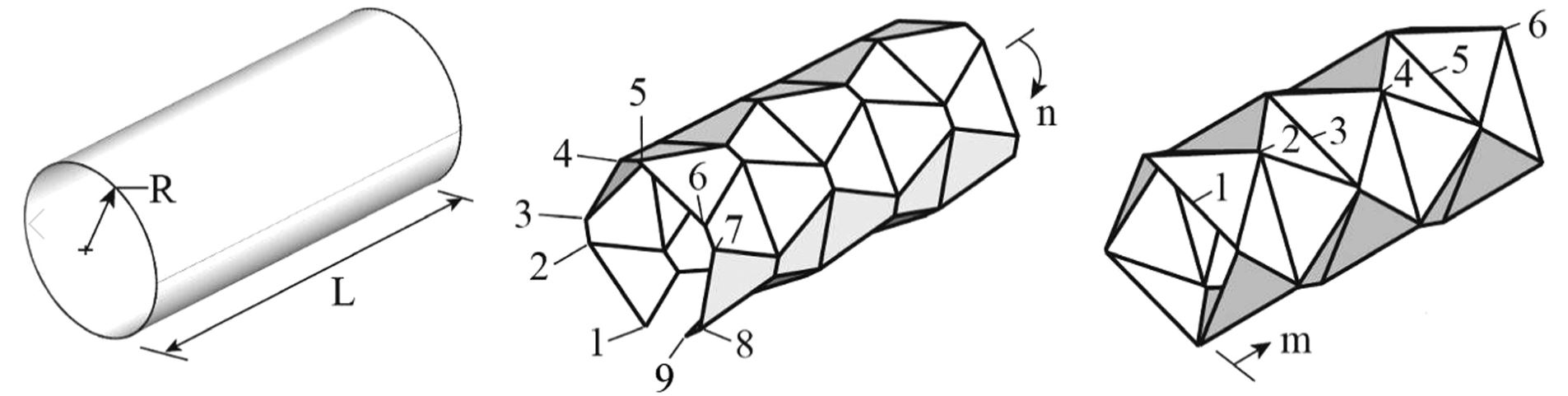

Elastic Buckling Shape Control

Curved-crease origami can control the shape of elatically-buckled tubes. By using pre-embedded curved-crease origami patterns in thin-walled cylinders, the failure mode can be pre-determined as a stabilized high-order elastica surface, which manifests via a diamond buckling mode. Measurements of the deformed surface show the buckled shapes to have a near-exact correspondence to the analytical curved-crease origami description. Further information: DOI: 10.1016/j.ijmecsci.2018.11.005.

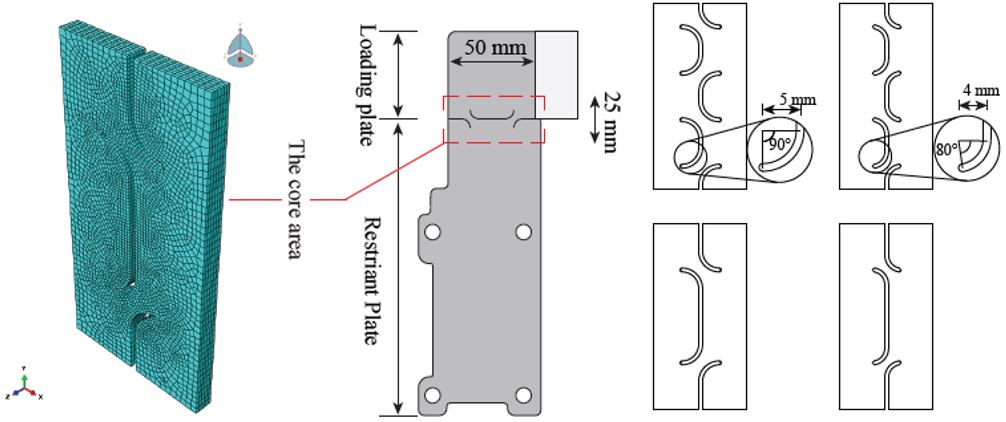

Rotational Stiffness in Steel Fold Lines

Digitally-fabricated hinge lines simplify and expedite the assembly of complex folded and origami-inspired steel structures, ensuring accurate and predictable hinge stiffness. This allows for rapid simulation of folded structures using simplified analysis. The research advances understanding of the elastic-plastic rotational behavior and folding mechanics of these hinges, including thick panel clash behavior. An ‘over-kerf’ manufacturing strategy is developed to eliminate clash in steel plates up to 3mm thick. Further information: DOI:10.1016/j.engstruct.2020.110218.

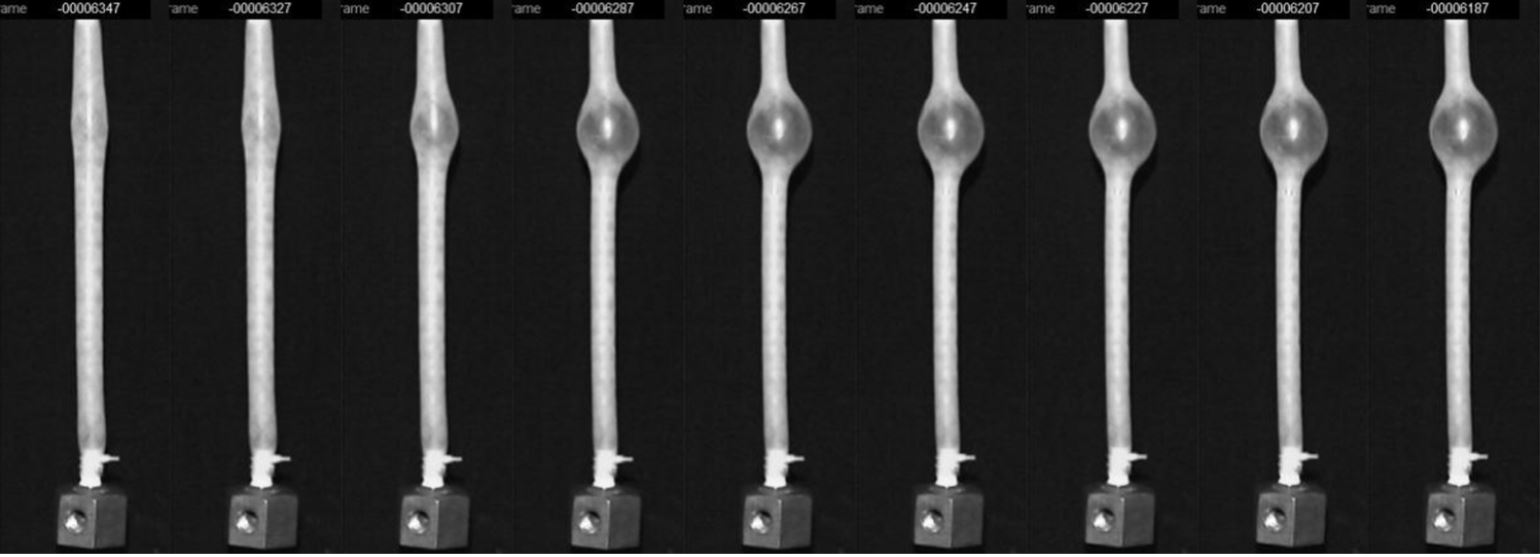

Propagation Buckling

Origami-inspired tubular geometries possess a geometric texturing than can improve resistance to propagation buckling failures in pipelines. Experimental and numerical investigations both showed that this behaviour also occurs in localized instabilities (bulging) of elastic textured tubes, with an increase in critical and propagation pressures as compared to smooth tubes. Further information: DOI: 10.1016/j.ijmecsci.2016.07.026.

Related Publications

Shi, Q., & Gattas, J. M. (2021). Finite element analysis and thick-panel clash behaviour of steel fold-lines. In International design engineering technical conferences and computers and information in engineering conference (Vol. 85451, p. V08BT08A040). American Society of Mechanical Engineers. https://doi.org/10.1115/DETC2021-69513

Shi, Q., Heitzmann, M. T., & Gattas, J. M. (2020). Nonlinear rotational stiffness and clash prevention in perforated steel fold lines. Engineering Structures, 209, 110218. https://doi.org/10.1016/j.engstruct.2020.110218

Lee, T.-U., Yang, X., Ma, J., Chen, Y., & Gattas, J. M. (2019). Elastic buckling shape control of thin-walled cylinder using pre-embedded curved-crease origami patterns. International Journal of Mechanical Sciences, 151, 322–330. https://doi.org/10.1016/j.ijmecsci.2018.11.005

Shi, Q., Heitzmann, M. T., & Gattas, J. M. (2018). Analysis of steel origami tube with nonlinear rotational hinge stiffness. In Proceedings of the 25th australasian conference on the mechanics of structures and materials (ACMSM25).

Shi, Q., Shi, X., Gattas, J. M., & Kitipornchai, S. (2017). Folded assembly methods for thin-walled steel structures. Journal of Constructional Steel Research, 138, 235–245. https://doi.org/10.1016/j.jcsr.2017.07.010

Ramdoo, D., O’Connor, L., Guo, Zhiming, Fernando, D. N., Heitzmann, M. H., & Gattas, J. M. (2017). Low-cost folding fabrication of natural fibre composite thin walled columns. In Proceedings of 8th international conference on structural engineering and construction management (ISECM2017).

Guo, Z., Gattas, J., Wang, S., Li, L., & Albermani, F. (2016). Experimental and numerical investigation of bulging behaviour of hyperelastic textured tubes. International Journal of Mechanical Sciences, 115, 665–675. https://doi.org/10.1016/j.ijmecsci.2016.07.026

Guo, Z., Gattas, J., Karampour, H., Wang, S., Albermani, F., et al. (2016). Numerical analysis on the buckling behaviour of curved-crease origami pipelines. In The twelfth ISOPE pacific/asia offshore mechanics symposium. International Society of Offshore; Polar Engineers. Retrieved from https://espace.library.uq.edu.au/view/UQ:499773

Garrett, D., You, Z., & Gattas, J. M. (2016). Curved crease tube structures as an energy absorbing crash box. In International design engineering technical conferences and computers and information in engineering conference (Vol. 50169, p. V05BT07A017). American Society of Mechanical Engineers. https://doi.org/10.1115/DETC2016-59784

Shi, X., & Gattas, J. M. (2015). Design and folded fabrication of novel self-braced triangular structural sections and frames. In International conference on performance-based and life-cycle structural engineering (pp. 792–798). School of Civil Engineering, The University of Queensland. https://doi.org/10.14264/uql.2016.424

Gattas, J. M., & Chen, Y. (2015). Synthesis of folded frame structures from cube-type and eggbox-type kirigami geometry. In ASME 2015 international design engineering technical conferences and computers and information in engineering conference (pp. V05BT08A031–V05BT08A031). American Society of Mechanical Engineers. https://doi.org/10.1115/DETC2015-46433